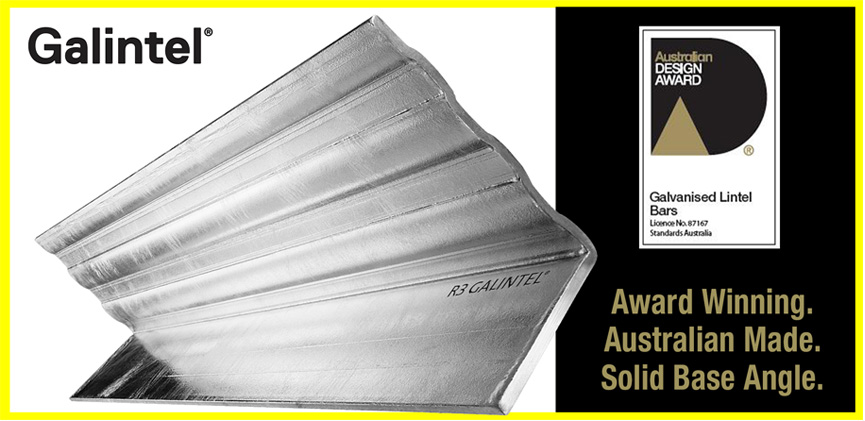

When asked what our most sought-after lintel is in our product range, our Solid Base Angle would be the clear front-runner, every time.

“Solid Base Angles are the backbone of our lintel business,” Galintel Business Development Manager Pernell Briggs said.

“We pioneered the Solid Base Angles in Australia in the 1970s winning an Australian Design Award & have been manufacturing them since. They are without a doubt the most popular product we sell.”

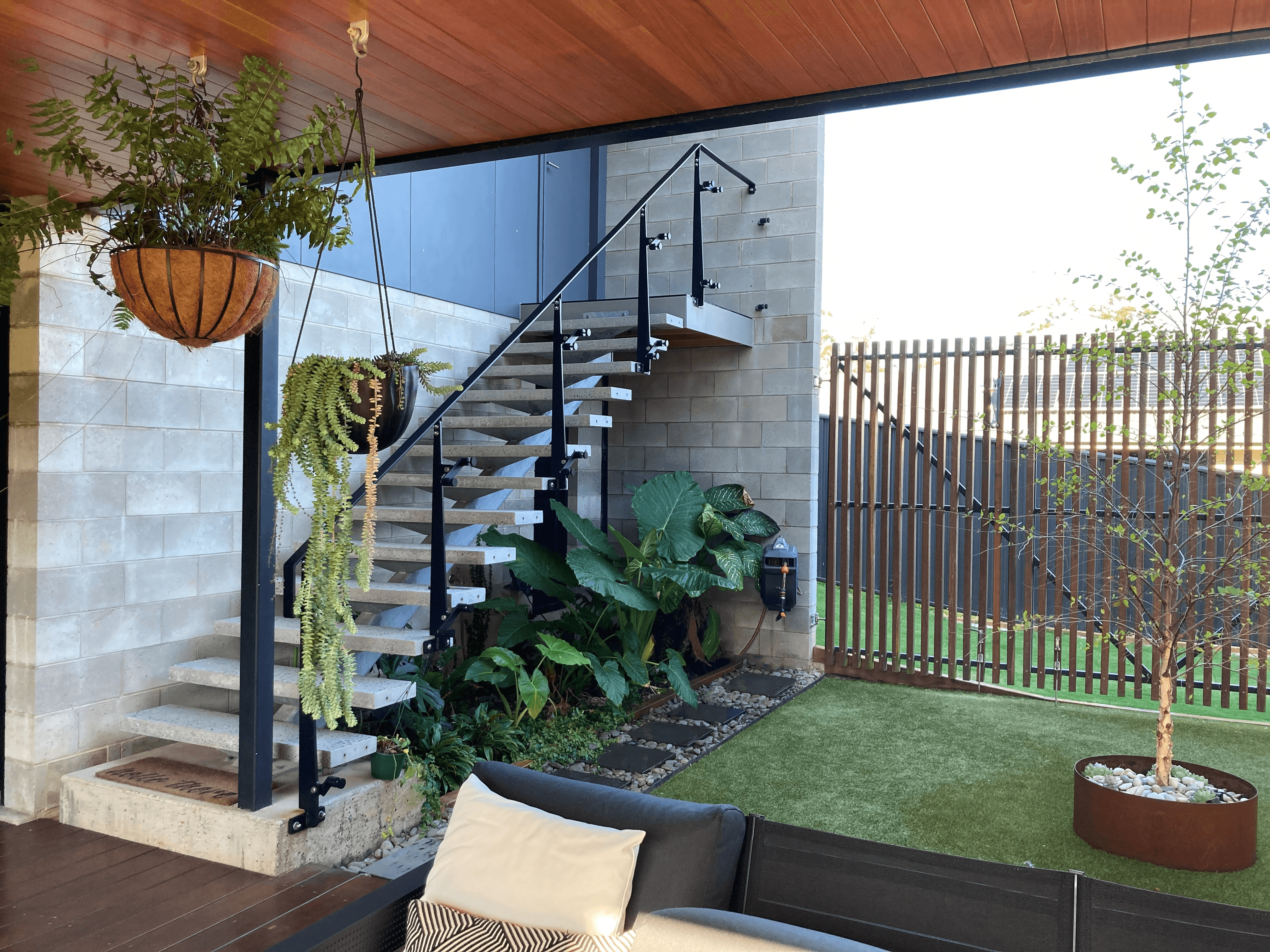

The innovative Solid Base Angle steel lintels are used to support brickwork over clear openings in residential builds. They feature a unique ribbed vertical leg which helps provide a recess for mortar to bond with brick & lintel.

What this does is help improve the bonding of mortar, brickwork, and steel to form a composite beam of superior strength and load-bearing capacity.Mr Briggs said Galintel Solid Base Angles are popular brick support used in the building industry.

“They are a great option to use above windows and door openings, offering builders a simple solution for supporting bricks and blocks.”

“Mr Briggs said, to achieve ultimate performance mortar must be present at all contact surfaces between brick & lintel, this is known as composite design & the unique bond providing a masonry-like beam equal, if not superior to other masonry beams.

“It is also vital that lintels are propped before bricklaying. Props must be no further than 1.2m apart and must remain in place until the mortar has fully cured,” he said.

Props must be no further than 1.2m apart

WHY CHOOSE OUR AUSTRALIAN-MADE SOLID BASE ANGLES

On top of being easy to install, the Solid Base Angles are hot-dip galvanised to comply with all the relevant Australian Building Codes and Standards.

By hot-dip galvanising our lintels, they are more durable and have a longer service life. The fact is the Hot-dip galvanised coating allows Solid Base Angles to achieve a minimum R3 Durability rating.

“The section design & mass of the section compared to alternatives means they are easier to transport, store, and install in your build,” Mr Briggs said.

“They are also manufactured by us using Australian steel, so you know you’re getting the very best quality, and a product that can be easily identified to give you that extra peace of mind,” Mr Briggs said.

What’s more, the Solid Base Angles are available off-the-shelf from our large network of authorised distribution partners and resellers.

“A quick trip to your local hardware store, and you can get your hands on one of these lintels. They’re so convenient,” he said.

SOLID BASE ANGLE FEATURES:

• The lintels are available in two sizes to suit all residential builds:

Sizes:

100 x 100 x 6mm

150 x 100 x 6mm

Length range:

900/1200/1500/1800/2100/2400/2700mm

1800/2100/2400/2700/3000/3300/3600/4000mm

• Fully Hot Dip Galvanised to AS/NZS4680

• Achieve an R3 Durability Rating to AS/NZS2699.3

• Fully engineered and University-tested

• Australian designed and manufactured

• Come with a full product warranty

• Stencilled

• Labelled and barcoded

WANT TO KNOW MORE?

Head over to our Contact page to get in touch.